Our Views

How to Do a Feasibility Study of a Waste Management Plant

Developing a municipal solid waste (MSW) management plant is a complex undertaking. Before investing in design and construction, it’s essential to perform a feasibility study. This study evaluates whether the proposed waste management facility is viable from legal, technical, financial, environmental, and social perspectives. In this article, we provide a step-by-step guide to conducting a comprehensive feasibility study for an urban MSW plant. We’ll cover why these studies are important, break down the key components to analyze, discuss tools and methodologies commonly used, and share lessons learned from real-world projects in various regions. Finally, we offer practical recommendations for consultants and developers preparing such studies.

Introduction: Why Feasibility Studies Matter for MSW Plants

Investing in a waste management plant is a major decision with long-term implications for a city’s environment, public health, and finances. A feasibility study is the crucial first step in MSW plant development that helps stakeholders make informed decisions. This study acts as a risk management tool – it verifies that the project is practicable and sustainable before large resources are committed. By thoroughly examining all aspects of the project, a feasibility study can identify potential roadblocks early on (such as regulatory hurdles or economic shortfalls) and propose solutions or alternatives. In essence, it answers the question: “Is this project worth pursuing, and under what conditions?”

Feasibility studies are especially important in urban MSW projects because these projects often involve significant capital expenditure and must operate reliably for decades. A well-conducted study provides confidence to investors, government authorities, and the community that the proposed plant will meet its objectives – whether those are reducing landfill use through waste-to-energy conversion, increasing recycling rates, or improving sanitary disposal. It also ensures that the plant will comply with environmental standards and be financially viable in the local context. In summary, a feasibility study lays the foundation for a successful waste management facility by ensuring all critical factors are assessed and aligned with reality.

Step 1: Regulatory and Legal Analysis

The first component of a feasibility study is understanding the regulatory and legal framework. Waste management is highly regulated, so any new MSW plant must operate within local and national laws. In this step, you will:

- Review Waste Management Policies and Laws: Examine national and municipal regulations governing solid waste management. This includes waste management acts, environmental protection laws, public health regulations, and any specific legislation on waste treatment technologies (for example, laws on incineration emissions or requirements for recycling). Ensure the project aligns with the country’s waste management strategy or circular economy goals.

- Identify Required Permits and Licenses: Determine all permits the project will need. Common requirements include environmental impact assessment (EIA) approval, waste facility operating licenses, building and land-use permits, and health and safety permits. For instance, a waste-to-energy plant may require air emissions permits and an energy generation license if it feeds electricity to the grid. Ensure you understand the process and timeline for obtaining each permit, as regulatory approvals can be lengthy.

- Assess Legal Constraints and Responsibilities: Analyze who has the authority for MSW in the project area. Often, municipal governments are responsible for waste services – will the plant be municipally owned, or run as a public-private partnership (PPP)? Evaluate any legal provisions for PPPs or private sector involvement in waste management. Also, check if there are laws about engaging informal waste pickers or labor regulations that could affect staffing.

- Compliance Requirements: List specific standards the plant must meet. For example, emissions standards for an incinerator (dioxins, particulate matter, etc.), leachate treatment standards for a landfill, or quality standards for compost if you plan an organic waste composting facility. The feasibility study should confirm that the project can be designed to comply with all these requirements.

- Regulatory Incentives or Support: Identify if there are incentives or regulations that could benefit the project. Some jurisdictions have renewable energy feed-in tariffs or tax breaks for waste-to-energy projects, recycling targets that ensure demand for recycling facilities, or mandated landfill diversion targets. Knowing these can strengthen the case for the project or influence its design (for example, sizing a plant to meet a mandated recycling rate).

By completing the regulatory and legal analysis, you ensure the proposed plant fits into the legal context and that there are no “show-stopper” legal obstacles. It also clarifies the regulatory steps ahead so the project timeline can account for permit processes. Legal feasibility is fundamental: even a technically and financially sound project will fail if it cannot obtain the necessary approvals or if it violates established policy.

Step 2: Technical Feasibility Assessment

The technical feasibility step evaluates whether the project is technically practical and appropriately designed for the local waste stream and conditions. Key activities and questions in this phase include:

- Waste Characterization and Supply Analysis: Start by gathering data on the municipal solid waste that the plant will handle. Analyze the quantity of waste generated in the service area (tons per day/year) and its composition. For urban MSW, determine the fractions (organic matter, plastics, paper, glass, metals, etc.) and properties like moisture content and calorific value. This information is critical: for example, a high organic content and moisture level might favor composting or anaerobic digestion, while extremely low calorific value could challenge a combustion-based waste-to-energy facility. Ensure the study also projects future waste generation over the plant’s lifespan, accounting for population growth or improvements in collection coverage.

- Capacity and Siting: Based on waste supply, determine the plant capacity (throughput of waste the facility will process per day). Check if the proposed site is suitable – consider location relative to the waste sources (to minimize transport distances), availability of adequate land area, access roads, proximity to utilities (water, electricity), and distance from sensitive receptors like residences or schools. The site should also have space for future expansion if needed. Technical feasibility includes confirming that the site conditions (soil stability, flood risk, etc.) won’t impede construction and that infrastructure (e.g., roads for garbage trucks) can support the operations.

- Technology Selection: Evaluate various technology options for waste processing and choose the most appropriate one. Options for MSW include sanitary landfilling (with methane capture), mass-burn incineration (waste-to-energy), refuse-derived fuel (RDF) production, anaerobic digestion for organics (producing biogas), composting, recycling and materials recovery facilities (MRFs), or an integrated combination of these. The feasibility study should compare these alternatives on technical merits: e.g., Can the technology handle the local waste composition? Does it require pre-sorting or special equipment? Is the technology proven and maintainable in similar contexts? Consider the reliability and track record of each technology, especially in environments similar to the project location. For instance, mechanical-biological treatment (MBT) might work well if waste is mixed and resources for high-tech maintenance are limited, whereas a high-temperature incinerator might demand a consistent high-calorie waste stream and skilled operators.

- Design and Process Flow: Outline the conceptual design of the plant. This includes major equipment (weighbridges, sorting lines, shredders, furnaces or digesters, pollution control systems, etc.), process flow (from waste reception to processing and final residue disposal), and staffing/operation plan. Technical feasibility means confirming that all necessary components can be put together to form a working system. If the plant is waste-to-energy, estimate the energy generation (electricity or heat output) based on waste input. If it’s a recycling or composting facility, estimate outputs (tons of recyclables recovered, compost produced, etc.).

- Utilities and Infrastructure Needs: Determine supporting requirements such as water supply (for cleaning or boilers), power supply (for machinery, unless the plant self-generates), leachate and wastewater management systems, and roads/traffic management for waste delivery trucks. Check that these needs can be met at the chosen site. Sometimes a feasibility study will highlight the need for infrastructure upgrades (e.g., strengthening an access road or connecting to the power grid) as part of the project.

- Expertise and Operational Feasibility: Assess whether local teams can operate and maintain the plant, or if specialized training is needed. If a technology is very advanced, consider the supply chain for spare parts and technical support. A technically feasible solution should be robust enough to run given the available institutional capacity. This might involve planning for an initial period of technical assistance or training when the plant starts operation.

Throughout the technical analysis, it’s common to use scenario analysis – considering multiple configurations or technologies and comparing their outcomes. You might perform a preliminary life-cycle assessment (LCA) for each option to gauge the overall environmental efficiency (for example, comparing the greenhouse gas emissions of an incinerator vs. a landfill with gas capture over a 20-year span). By the end of the technical feasibility step, the study should clearly identify the recommended technical solution and demonstrate that it can work in practice for the given waste stream and local conditions.

Step 3: Financial and Economic Viability

No project can move forward without a solid understanding of its financial feasibility. This component of the study examines whether the waste management plant makes economic sense, both from a business/investment perspective and from a broader cost-benefit perspective for the community or municipality. Key elements are:

- Capital Expenditure (CAPEX) Estimation: Calculate the total upfront cost to implement the project. This includes costs for land acquisition (if not already provided), construction of facilities (buildings, roads, foundations), purchase and installation of equipment (incinerators, digesters, generators, sorting lines, vehicles like collection trucks or loaders, etc.), engineering and design fees, project management costs, and contingencies. Feasibility studies often provide a detailed CAPEX breakdown with line items, plus a contingency percentage to cover unforeseen expenses.

- Operational Expenditure (OPEX) Estimation: Project the ongoing annual costs to run the plant. OPEX typically covers staff salaries, fuel for equipment or generators, electricity for operations, chemicals or consumables (e.g., reagents for flue gas cleaning in an incinerator), maintenance and spare parts, insurance, administrative expenses, and the cost of disposing or treating any residues (like ash from incineration or rejects from sorting). Be sure to include the cost of compliance (environmental monitoring, permit fees) and any lease or debt service if the project is financed.

- Revenue Streams and Funding: Identify how the plant will generate income or recover costs. Common revenue sources for an MSW facility include tipping fees (the fees paid per ton of waste delivered to the plant, usually by municipalities or waste collectors), sale of energy (electricity or heat if it’s a waste-to-energy project, often through a power purchase agreement or feed-in tariff), sale of recovered materials (recyclable plastics, metals, paper) or products (compost, RDF, etc.), and possibly carbon credits or renewable energy credits if applicable. The study should forecast revenue based on realistic assumptions: e.g., how much electricity will be produced and at what tariff will it be sold? How high can tipping fees be set without political or public pushback? It’s important to align revenue assumptions with local market conditions – for instance, if recyclables fetch low prices in the region, counting on high recycling revenue would be unrealistic.

- Financial Analysis: Using the CAPEX, OPEX, and revenue projections, perform a detailed financial analysis. This usually includes preparing multi-year projections of cash flows for the plant. Key metrics to calculate are net present value (NPV) of the project (especially if comparing alternatives), the internal rate of return (IRR) or return on investment (ROI) for investors, and the payback period (how long until the project breaks even). A break-even analysis can determine the waste throughput or tipping fee required to cover costs. If the project is not financially viable on its own, the study should make this clear and possibly explore financing models like subsidies, grants, or blended finance to close the gap. For municipal projects, sometimes an economic cost-benefit analysis (CBA) is included – this goes beyond financial cash flows to account for societal benefits (e.g. avoided health costs due to better waste management, reduced greenhouse gas emissions) versus societal costs. A positive economic CBA can justify public funding or donor support even if pure financial ROI is modest.

- Sensitivity Analysis: Financial projections inevitably involve uncertainties (future waste quantities, energy prices, construction costs, etc.). To address this, include a sensitivity analysis on key variables. For example, evaluate how the IRR or annual operating margin changes if the waste supply is 20% lower than expected, or if the construction cost overruns by 15%, or if the electricity selling price is reduced. This analysis identifies the critical risk factors for financial viability. If a small change in one factor (say, the tipping fee) turns the project from profitable to loss-making, that factor deserves careful attention and mitigation.

- Economic Viability and Affordability: For public sector-driven projects, consider the affordability from the city’s perspective. Will the project reduce overall waste management costs compared to the status quo (like open dumping plus emergency cleanups)? Is the required tipping fee affordable for the municipality or private haulers? Often, feasibility studies for MSW plants will compare the cost per ton of waste managed under the new facility versus alternatives (like continuing to landfill) to illustrate value for money. Also, ensure that funding sources are identified: will this be financed by government budget, a loan, private investors in a PPP, or a combination? The study’s financial section should outline a viable financing plan, including potential investors or lenders and any need for financial support (for example, viability gap funding or tariffs adjustments).

By the end of the financial analysis, decision-makers should have a clear picture of whether the project is economically worthwhile and how it can be funded. If the numbers are borderline, the feasibility study might recommend changes (e.g., increasing the service area to get more waste and revenue, securing a higher energy tariff, or phasing the project to reduce initial cost). Financial viability is often the make-or-break factor for a project, so this section of the study must be rigorous and grounded in realistic assumptions.

Step 4: Environmental and Social Impact Assessment

Every waste management facility has impacts on the environment and the community. A feasibility study must include a review of potential environmental and social impacts and how they will be managed. In many cases, a formal Environmental and Social Impact Assessment (ESIA) or at least a preliminary environmental assessment is a required part of feasibility, especially if international funding is involved. Key considerations include:

- Environmental Impacts: Identify how the project could affect air, water, and soil. For an incineration or waste-to-energy plant, the primary concern is air emissions – pollutants like particulate matter, NOx, SO₂, heavy metals, and dioxins/furans. The study should confirm that modern flue gas cleaning systems (scrubbers, filters, etc.) will be in place to meet emission limits. If the project involves a landfill or bio-digester, consider leachate generation and ensure plans for leachate collection and treatment to protect groundwater. Noise and odor are other environmental factors: large facilities can produce significant noise (machinery, truck traffic) and odors (especially if handling organic waste or if waste is stored). Mitigation measures – such as enclosing waste processing areas, using biofilters for odor control, and restricting operating hours – should be outlined. Also, consider climate impact: the study might quantify greenhouse gas emissions with and without the project. Often, modern waste plants aim to reduce methane emissions from dumpsites or generate renewable energy, yielding a net climate benefit. If relevant, include a life-cycle environmental analysis comparing different scenarios (for example, the net CO₂-equivalent emissions of landfilling vs. incineration vs. composting the waste).

- Social Impacts: Evaluate how the project will affect local communities and stakeholders. Key questions: Is the site near residential areas, and will it cause nuisance or health concerns for neighbors? Will any land acquisition or resettlement be required (if people live or work on the chosen site)? Community acceptance is crucial – MSW projects, particularly waste-to-energy plants or landfills, sometimes face “Not In My Back Yard” (NIMBY) opposition. A feasibility study should gauge public sentiment and plan for stakeholder engagement, such as community meetings to explain the project benefits and safety measures. Another social aspect is the impact on informal waste pickers or recyclers: in many cities, informal sector workers depend on waste for income (picking recyclables at dumpsites). A new facility could disrupt their livelihoods. The study should propose measures to integrate or compensate these stakeholders – for instance, including a recycling center that provides jobs for former waste pickers, or offering job training programs.

- Regulatory Environmental Requirements: Ensure that the project can meet any required environmental assessment processes. For example, local law might require a full EIA report and public hearings before approval. The feasibility study often includes an Environmental Management Plan (EMP) outline with mitigation measures for identified impacts. It should show that the project can be made environmentally acceptable with proper design and management.

- Health and Safety: Consider worker safety and public health. Handling waste can pose hazards (pathogens, sharp objects, hazardous substances in mixed waste). The design should include safety features and protocols, such as protective equipment for workers, proper handling of medical or hazardous waste if it might be mixed in, and fire control systems (landfills and waste piles can catch fire; biogas facilities handle combustible gas). Public health improvements from the project (like reduced open dumping, fewer disease vectors such as rats and flies) should also be noted as positive impacts.

- Social Benefits: On the positive side, an MSW plant often brings local benefits like employment opportunities, cleaner neighborhoods due to better waste disposal, and sometimes community infrastructure (roads or electricity) as part of the project. The study should mention these to provide a balanced view. For example, a waste-to-energy plant could supply stable power to the grid, or a composting plant could provide affordable compost to local farmers – these indirect benefits strengthen the case for the project.

By addressing environmental and social factors, the feasibility study ensures that the project is not only technically and financially viable but also sustainable and responsible. It’s far easier to modify or reconsider a project at the study stage than to fix environmental or social issues after construction. Therefore, this step is critical to avoid future conflicts and to secure community support and necessary environmental clearances.

Step 5: Risk Analysis and Mitigation

Even after careful planning, every project faces uncertainties. The feasibility study should include a systematic risk analysis, identifying potential risks across all the areas we’ve discussed and suggesting mitigation strategies for each. This step ties together findings from previous sections to ensure that decision-makers are aware of what could go wrong and how to address it. Key components of risk analysis include:

Identifying Risks: List out all significant risks that could affect the project’s success. Typical risk categories for a waste management plant are:

- Technical risks: Equipment failure, technology underperformance, difficulty in operating advanced technology, or construction challenges (e.g., unexpected site conditions).

- Financial risks: Cost overruns during construction, lower revenue than forecast (perhaps due to a lower waste intake or lower market prices for energy/materials), higher operating costs (like fuel price spikes), or inability to secure financing on expected terms.

- Regulatory risks: Delays or failure in obtaining permits, changes in laws or regulations (for example, a new law that bans waste incineration or changes waste import/export rules), or changes in government priorities.

- Market/Demand risks: If the project relies on selling outputs (power, recyclables, compost), there’s a risk of not finding a stable market or of price volatility. Also, if waste collection systems are weak, the plant might not receive the expected waste volume (feedstock risk).

- Environmental/Social risks: Strong public opposition causing delays or cancellation, lawsuits over environmental concerns, or unanticipated environmental problems (like higher pollution levels than expected).

- Operational risks: Lack of skilled personnel to run the plant, labor disputes, or supply chain issues for spare parts and consumables.

- Force majeure: Natural disasters (floods, earthquakes) or other unforeseen events that could damage facilities or disrupt operations.

Risk Evaluation: For each identified risk, assess its likelihood of occurring and the severity of its impact. Some studies use a risk matrix (low/medium/high) to prioritize risks. For example, a moderate likelihood of a cost overrun of 10% might be a medium financial risk, whereas the risk of not getting a permit could be low likelihood but very high impact (since without it the project cannot proceed). This evaluation helps focus the mitigation efforts on the most critical risks.

Mitigation Strategies: Propose measures to reduce each high or medium risk to an acceptable level. Mitigation can take various forms:

- For technical risks, you might recommend using a proven technology supplier with performance guarantees, or include extra redundancy in the system (backup equipment) to ensure reliability.

- To address financial risks, set aside contingency funds in the budget, obtain fixed-price construction contracts, or negotiate power purchase agreements with fixed tariffs to secure revenue. Insurance can cover certain risks like damage or accidents.

- For regulatory risks, maintaining good communication with authorities and perhaps breaking the project into phases can help (for instance, start with a pilot project to prove concept and ease the permitting).

- For feedstock risk (not enough waste), a mitigation could be to widen the service area (bring waste from neighboring towns), sign long-term waste supply agreements with municipalities, or design the plant to be flexible (capable of co-processing other materials or scaling down if needed).

- Social risk mitigation often involves stakeholder engagement: conducting public awareness campaigns about the project’s benefits, addressing community concerns transparently, and incorporating community feedback in the project design (like adding odor control or offering local development projects as compensation).

- Operational risk mitigations include training programs for staff, hiring experienced operators (perhaps via an international operator contract initially), and securing maintenance contracts for critical equipment.

Residual Risk and Go/No-Go Decision: After mitigation measures, indicate the residual risk. The feasibility study should conclude whether any remaining risks are unacceptably high. If so, either further action is needed or the project might be deemed infeasible at this time. In most cases, a feasibility study doesn’t outright cancel a project but may recommend significant changes to reduce risk (for example, if an incinerator is too risky, the study might recommend a different technology like anaerobic digestion combined with landfill).

Performing a thorough risk analysis ensures that no surprises derail the project later. It demonstrates to stakeholders (especially investors and lenders) that the project team is aware of potential pitfalls and has a plan to manage them. In fact, many lenders will scrutinize the risk section of a feasibility study to decide if the project’s risk level fits their appetite. Therefore, this section ties all prior analysis together and adds confidence that the project can be executed with manageable risk.

Analytical Tools and Methodologies Used

Throughout the steps above, several analytical tools and methodologies are used to strengthen the study’s rigor:

- Cost-Benefit Analysis (CBA): This technique is often used in the financial/economic viability stage, especially for publicly funded projects. It quantifies and compares the total expected benefits to society (e.g., extended landfill life, energy generated, jobs created, reduced pollution) against the total costs (capital, operating, environmental externalities). If benefits outweigh costs (often demonstrated by a positive net present value when monetizing everything, or a benefit-cost ratio > 1), the project is economically justified. CBA helps capture intangible benefits or costs that pure financial analysis might miss (like the societal cost of greenhouse gas emissions or the public health benefit of cleaner streets).

- Life-Cycle Assessment (LCA): LCA is a method to evaluate the environmental impacts of a system “from cradle to grave.” In waste management feasibility studies, LCAs can compare different waste treatment options. For example, an LCA can illustrate how incinerating waste might reduce methane emissions from landfills but increase CO₂ from combustion, or how recycling saves energy and emissions by offsetting virgin material production. By analyzing factors like energy use, emissions, and resource consumption across each option’s life cycle, decision-makers get a clearer picture of which technology is environmentally preferable overall.

- Financial Modeling (Spreadsheet Models): A detailed financial model (usually in Excel or specialized software) is built to project cash flows year-by-year. This model incorporates assumptions on waste growth, costs, revenues, financing (loans interest rates, debt repayment schedules), tax implications, etc. The model allows testing different scenarios easily (e.g., adjusting the waste input or costs) to see effects on profitability. It’s an indispensable tool to derive NPV, IRR, ROI, and to perform the sensitivity analysis described earlier.

- Sensitivity and Scenario Analysis: As mentioned, sensitivity analysis systematically varies one input at a time (or a few at once) to test outcomes. Scenario analysis might bundle assumptions into coherent scenarios – for instance, an optimistic scenario (higher waste and revenue, low costs), a pessimistic scenario (lower waste, high costs), and a base case. These analyses demonstrate the range of possible outcomes and help in planning contingencies.

- Stakeholder Analysis: On the social side, consultants might use stakeholder analysis methods to map out all parties affected by the project (residents, businesses, waste workers, government entities, NGOs) and their concerns or influence. This helps formulate engagement strategies as part of the social feasibility component.

- Risk Assessment Matrix: As part of risk analysis, a matrix or register is often used. It lists risks, scores them by probability and impact, and tracks proposed mitigation measures and owners for each risk. This tool helps ensure no risk is overlooked and provides a clear summary in the report.

Using these tools lends credibility to the feasibility study – each conclusion or recommendation is backed by data and systematic analysis rather than guesswork. For example, if the study recommends a certain technology because it yields the best cost-benefit result and lowest emissions per the LCA, that is a strong, defensible position. Likewise, a robust financial model will show precisely under what conditions the project remains profitable. In professional practice, these methodologies are considered standard, and their inclusion in the report will meet the expectations of financers, government reviewers, and other experts.

Lessons from Real-World MSW Feasibility Projects

Feasibility studies for waste management plants have been carried out in diverse contexts worldwide. While every location has unique conditions, there are common lessons and insights from real projects in regions such as Africa, Latin America, and Asia:

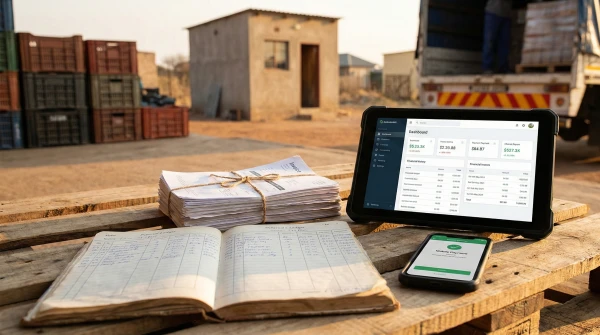

- Reliable Data is Gold: Many feasibility studies in developing cities struggle with data gaps – accurate information on waste generation and composition is often scarce. Lessons from past projects show the importance of conducting local waste audits and surveys. For instance, a city in Africa may have assumed a certain waste volume based on national averages, only for a detailed study to find actual collected waste was much lower due to inefficiencies in collection. Without ground-truth data, projects risk being over- or under-designed. So, allocate time and resources in the study for primary data collection (waste sampling, interviews, field measurements).

- Local Context Determines Technology: A solution that works well in one country might fail in another if local conditions differ. Real-world examples include expensive incineration plants that were built in some Asian and African cities but then underperformed because the waste was too high in moisture and organics (making it difficult to burn and yielding low energy). Those projects taught that technology must match the waste profile and infrastructure. Often, simpler or modular approaches provide more sustainable results in developing contexts – such as improving recycling systems, composting the abundant organic fraction, and upgrading landfills, before considering mass-burn incineration. Feasibility studies should critically assess imported “high-tech” solutions and perhaps favor proven, low-maintenance technologies if local technical capacity is limited.

- Financial Sustainability is a Challenge: Lessons from Latin America and elsewhere highlight that even technically successful waste facilities can run into trouble if financial planning is weak. Many municipal projects rely on government budgets or donor grants and face difficulty when those funds wane. Feasibility studies increasingly examine long-term funding models: for example, how to set waste tariffs or tipping fees at a level that balances cost recovery with public affordability. A common insight is that public willingness-to-pay for waste services is often low in developing regions, so innovative financing may be needed (such as cross-subsidies, or monetizing energy and recyclables to subsidize operations). A study in one Latin American city showed that a waste-to-energy plant could only be viable with a significant increase in the city’s waste fee or with external support; as a result, the city opted to start with a smaller pilot project. The takeaway: be realistic about revenue and consider phased or scaled solutions that the local economy can support.

- Environmental and Social buy-in: Real projects demonstrate that early engagement with the community and other stakeholders can make or break a project. In some instances, lack of public consultation led to protests and cancellation of otherwise sound projects. Conversely, cities that involved citizens in planning (for example, educating them about the benefits of closing an open dumpsite and opening a sanitary landfill, or creating programs to include informal recyclers) saw smoother implementation. A feasibility study should thus incorporate a stakeholder engagement plan and reflect community feedback. In regions of Asia and Africa, integrating the informal waste sector into new systems (by offering them roles in recycling cooperatives or jobs in the new facility) has been a key success factor. It addresses social impacts and leverages local knowledge.

- Phased Implementation: Another insight is that staggering project components can reduce risk. Instead of implementing a massive integrated facility all at once, some successful cases started with one aspect – for example, build a sorting and composting facility first to handle organic waste (common in African and South Asian waste streams), while continuing to use existing landfills for residuals, then later add a waste-to-energy unit when waste quantity and management capacity increased. This phased approach, often recommended by feasibility studies, allows demonstration of success on a smaller scale, capacity building, and adjustments along the way. It’s a practical strategy in places where funding and experience must accumulate gradually.

- Policy and Institutional Support: Feasibility studies have noted that even a well-designed project needs an enabling environment to thrive. For instance, a project in an African city foundered because local regulations didn’t allow the municipality to charge adequate fees, and waste collection remained erratic – meaning the plant never got enough waste. Meanwhile, countries that established strong national policies (like mandating closing of open dumps, or incentivizing energy from waste) provided a fertile ground for successful projects. The lesson is to consider the broader system: sometimes the feasibility study will recommend reforms or capacity-building efforts for the local waste management authority as part of the project. In Latin America, technical assistance to municipal waste departments often went hand-in-hand with new infrastructure projects, ensuring the institutions could run the new systems effectively.

In summary, real-world projects teach us that context matters enormously. A feasibility study shouldn’t just copy-paste a solution from elsewhere; it should digest these lessons and tailor the project design to local realities. Flexibility, stakeholder engagement, and realistic financial planning are recurring themes in successful MSW plant projects globally.

Practical Recommendations for Preparing Feasibility Studies

For professionals – consultants, engineers, or project developers – embarking on a feasibility study for a municipal waste management plant, here are some practical tips to ensure a high-quality outcome:

- Assemble a Multidisciplinary Team: Feasibility studies require expertise in engineering, finance, environmental science, social assessment, and legal/regulatory matters. Make sure your team covers all these areas. For example, have a waste engineer for technical design, an environmental specialist for EIA aspects, a financial analyst for the economic model, and so on. This ensures each component of the study is robust.

- Engage Stakeholders Early: Don’t conduct the study in a vacuum. Early in the process, meet with key stakeholders – the municipal waste department, environmental regulators, community leaders, existing waste collectors or informal sector representatives, and potential off-takers (like the power utility if you plan energy production). Their inputs will provide valuable information (such as historical issues, public concerns, or willingness to participate) and help build buy-in. It’s easier to incorporate stakeholder concerns into the project design now than to face resistance later.

- Ground the Study in Data: Use actual data as much as possible. Conduct field investigations – waste composition studies, timing how collection is done, surveying dumpsites, analyzing existing cost records, etc. If you must use assumptions, explain and justify them (for instance, if you assume waste generation will grow 5% a year, tie it to expected population growth or economic trends). Transparent and evidence-based analysis builds credibility. Also, cross-check data from multiple sources (municipal records, academic studies, similar cities) to sense-check your numbers.

- Compare Alternatives and Be Objective: A good feasibility study doesn’t just champion a single idea; it evaluates alternatives fairly. Make sure to examine at least a few different scenarios (different technologies, different scales, different sites if applicable). Document the pros and cons of each and provide a clear rationale for the recommended option. This way, decision-makers see that you’ve considered options and chosen the one that best fits the project goals and constraints.

- Incorporate Buffer and Flexibility: When estimating costs and schedules, include reasonable contingencies. Infrastructure projects often face delays or unexpected expenses – acknowledging this in the study (say, by adding a 10-15% contingency in the budget and a few extra months in the schedule for approvals) makes it more realistic. Also, design flexibility into the project where possible, for example modular expansion capability or adaptable technology, in case conditions change (like waste quantities rising faster than expected).

- Focus on Environmental Compliance and Community Benefits: Given the scrutiny waste projects receive, ensure your study highlights how the plant will meet or exceed environmental standards and what benefits it brings to the community. This could be improved cleanliness, reduced pollution, job creation, or even electricity for local use. Including these benefits in your narrative can help gain support from both officials and the public. If there are negatives (e.g., the need to relocate some informal recyclers), propose a mitigation or compensation plan in the study. Responsible planning is part of feasibility.

- Plan the Implementation Roadmap: Don’t stop at “it’s feasible.” Outline the next steps to move the project forward. This might include a high-level implementation plan: How long will detailed design take? What is the procurement strategy (e.g., will it be a design-build contract, or separate bids for equipment)? Is there a need for an operator or a training program? Identifying these next steps in the feasibility report helps the project sponsors understand what’s required to actually realize the project.

- Review and Peer-Review: Before finalizing the study, have internal or external experts review it. Fresh eyes can catch any biases, errors, or weak assumptions. Often, international funding agencies or government ministries have their own checklist for what a feasibility study must cover – make sure you’ve addressed all required points. Quality control at this stage prevents costly mistakes later.

By following these recommendations, consultants and developers can produce a comprehensive and credible feasibility study that will serve as a strong foundation for the waste management plant project. Remember that the feasibility study is often the document that funding decisions are based on – it should tell a convincing story that the project is needed, beneficial, and achievable. A thorough study not only facilitates approvals and financing but also serves as a reference blueprint during implementation, increasing the chances that the project will ultimately succeed in delivering better waste management for the community.